Stihl Trimmer Serial Number Location

- Stihl Hedge Trimmer Serial Number Location

- Stihl 029 Serial Number Location

- Stihl String Trimmer Serial Number Location

- Stihl Blower Serial Number Location

String Trimmer Equipment Description Equipment Number Manufacturer Brand Model # Serial Number Warranty Purchase Price Purchased Location Brushcutter 381 Stihl Stihl FS286 Theft rtn $419 Crater CS. Almost impossible on a stihl. On newer huskies, there's a 2 digit date code off to the side of the serial #. On older black tag huskies, the 1st # is the year, followed by the week. Stihl power pruner serial number The serial numbers on the FS130, HL90K,HT101 and BG55 would be on stickers if they are still there. The MS250 serial numbers are located on a 'flat' by the side of the exhaust and sprocket cover.

Model, Part, & Serial Number. The model, part, and serial number can printed on a sticker on the base of the trimmer. Model, Part, & Serial Number. The model, part, and serial number can also be stamped onto a plate on the base of the trimmer. For example: Model Number: 128LD Part Number: 952711948 Serial Number: 06. This video provides helpful tips to identify where the model number is located on a string trimmer. Part testing, repair procedures and replacement parts are not designed to work on all models. Messages: 2,742. Likes Received: 291. Location: Hoot Owl Hollar. GEOD998 said: ↑. “Hello, I'm a newbie and very sorry if this is the wrong place for this-but I did try to search for similar post-to no avail.I have an older Stihl trimmer-it's a professional model with the 'bicycle handles' I bought it back in the 90s.

Will a 10% (E10) blend of ethanol hurt my gas-powered STIHL product?

All STIHL gasoline-powered engines can be used with up to a 10% (E10) blend of ethanol in the gasoline/engine oil mix. We also recommend that if a unit will be left unused for more than 30 days that it be stored 'dry.' This means emptying the fuel tank and then restarting and letting the unit run until all the fuel is consumed and the engine stops. For maximum performance and engine life expectancy, we also recommend using STIHL HP Ultra 2-cycle engine oil.

Note: STIHL recommends use of fuel with no more than 10% ethanol content. Using fuel with greater than 10% ethanol content may cause damage to your equipment and may void your STIHL warranty. Learn More…

My chainsaw will start and idle but won't run or stalls when I go to full throttle. What's wrong?

There are several things you can check. First, make sure that you are using fresh fuel mix (never store or use fuel mix older than 60 days in can or fuel tank). Second, clean spark arrester screen in the muffler. Third, replace fuel filter in fuel tank. Fourth, clean or replace air filter. If none of these work, please take the machine to your local authorized STIHL servicing Dealer for evaluation.

Learn more about fuel concerns

Read more about storing your outdoor power equipment

Why does my chainsaw flood?

The most common reason is due to too many attempts trying to start the machine in the choke position. When starting a unit, make sure to follow the starting instructions in your instruction manual. The manual provides the proper instruction for starting procedures, but there are many conditions that may affect how the unit starts. A good rule of thumb to follow is to remember that when placing the switch control to the full choke setting, more liquid fuel and less air flow into the combustion chamber in order to create a higher chance for ignition. Pulling the rope more than two to three times in this setting may flood the engine. The operator should move the Master Control Lever™ or choke lever from the full choke setting after three to four pulls even if the engine does not fire. Moving the lever to the next setting, the half choke or part throttle position will allow more air into the combustion chamber and help resolve the flooding condition.

Why does my saw leak bar oil?

The way our units lubricate a chain, most of the oil is distributed around the inside of the bar rails as it is circulated by the oil reservoirs in each drive link of the chain. The amount of oil being circulated inside the bar at any given time can be between .3 and .5 oz. As a general rule of physics, the oil will be pulled down by gravity once the chain stops turning, collecting at the bottom of the bar and seeping through the chain to puddle underneath the bar & chain assembly as well as under the drive sprocket. The fact that it appears to be continuing to seep after the unit is cut off for several days is owed to the viscosity of the oil and the anti-flinging compound (lithium) mixed with the oil at the refinery. These factors give the oil a very thick consistency, which in turn explains a slower flow rate. This condition is deemed to be normal for any chainsaw with a similar bar & chain lubricating system.

If the unit continues to seep oil after a few days, the problem may be the vacuum relief valve located in the side of the engine housing between the oil output hole and the bar stud(s). This valve has an internal spring and ball type arrangement with the ball pressed against the vent hole of the casing of the valve, when the tank develops a vacuum from the normal process of the oil being pumped out. The ball is pulled away from the hole, allowing air to enter into the tank and break the vacuum so that oil can continue to flow to the bar and chain assembly. Once the vacuum is relieved, the spring pushes the ball back against the hole of the valve casing. Sometimes debris may become trapped between the ball and the hole. This would cause the oil to keep 'weeping' because there must be some measure of vacuum in the tank to keep the oil from flowing freely once the unit is shut down. More often than not, all one needs to do is to take a small pin or needle and push it into the hole of the valve (identifiable as a small silver disk with a small hole in the center) about 6 or 7 times to loosen the debris. This should re-seal the orifice and keep the oil from seeping from the output hole when the saw is stored.

How do I adjust the bar and chain on my chainsaw?

Please refer to your instruction manual under the headings: Mounting Bar and Chain, Tensioning the Saw Chain and Checking Chain Tension.

What is kickback?

Kickback occurs when the moving saw chain near the upper quadrant of the bar nose contacts a solid object or is pinched. The reaction of the cutting force of the chain causes a rotational force on the chainsaw in the direction opposite to the chain movement. This may fling the bar up and back in an uncontrolled arc mainly in the plane of the bar. Under some cutting circumstances the bar moves towards the operator, who may suffer severe or fatal injury. Kickback may occur when the nose of the guide bar is pinched unexpectedly, unintentionally contacts solid material in the wood or is incorrectly used to begin a plunge or boring cut. It may also occur during limbing. The greater the force of the kickback reaction, the more difficult it becomes for the operator to control the saw. Many factors influence the occurrence and force of the kickback reaction. These include chain speed, the speed at which the bar and chain contact the object, the angle of contact, the condition of the chain and other factors.

What protective gear is required for chainsaw operation?

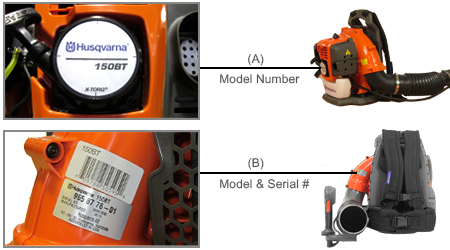

Where do I find my serial number?

Most serial numbers are stamped in the motor housing or crankcase to the left or right of the muffler looking down from the top on a flat surface. They will in most cases be 9 digits long and begin with the number 1, 2 or 5.

What do I need to know about chainsaw bar and chain lubrication?

For automatic and reliable lubrication of the saw chain and guide bar use only an environmentally compatible quality chain and bar lubricant with non-fling additive or the rapidly biodegradable STIHL BioPlus™ is recommended. The service life of the chain and guide bar depends on the quality of the lubricant. It is therefore essential to use only a specially formulated chain lubricant.

STIHL Bar and Chain Oil

Can I adjust my own carburetor?

The carburetor comes from the factory with a standard setting. This setting provides an optimum fuel-air mixture under most operating conditions. With most carburetors, it is only possible to adjust the engine idle speed within fine limits. Quite often adjusting the carburetor will not solve acceleration issues. To find the correct setting for your machine, please refer to your instruction manual. If you do not have a copy of your instruction manual, please go to our product manual webpage where you can download a PDF version.

Why do the instructions tell you to wash your protective chainsaw chaps before using?

These protective garments contain pads of cut-retardant material designed to reduce the risk or severity of injury to the body parts covered by the pads in the event of contact with a rotating chain. The fibers in the pads provide extra layers of material and are designed to rip apart if they come into contact with the moving chain and to clog the sprocket and stop the chain in certain circumstances. In some contacts, the pads may stop the chain. In other contacts, the pads will resist the cutting process only for a fraction of a second. The actual degree of protection afforded will vary with the speed of the chain at the time of contact, the power and torque of the saw, the design of the chainsaw sprocket and similar factors. Follow the washing instructions. Improper care may destroy cut-retardant properties of the material. During shipping these pads may become compressed. By washing them prior to use and weekly during regular use, these pads fluff up and offer maximum protection.

My STIHL chainsaw was stolen. Do you track them?

STIHL Inc. maintains a Stolen Unit Database. If your STIHL product was stolen, please report it stolen to your local law enforcement agency. Then contact us with your name, address, model number and serial number. If the unit was registered at the time of purchase, we can have it added to the Stolen Unit Database.

Can I send my chainsaw back to STIHL for repair?

STIHL Inc. does not accept product for repair or refurbishment. Please see your local authorized full-line STIHL servicing Dealer.

Stihl Hedge Trimmer Serial Number Location

What is the correct spark plug gap for my STIHL trimmer, chainsaw, or blower?

What is the minimum compression for my STIHL chainsaw?

Generally the minimum is 110 lbs. of compression. However, this will vary by model and compression readings alone are not enough to determine the condition of the engine. Compression gauges are not always accurate and different engines will provide different results.

How can I tell when my STIHL chainsaw was made?

STIHL does not incorporate production dates into our serial numbers.

How often should I have my STIHL chainsaw tuned up?

Please refer to the Maintenance Schedule which can be found in the instruction manual.

Does STIHL offer an electric start chainsaw?

STIHL does not offer an electric start unit. We do, however, offer our Easy2Start™ system on some models.

What is the recommended procedure for preparing my STIHL chainsaw for long term storage (over 30 days)?

Stihl 029 Serial Number Location

Only if you plan to 'mothball' your lawn trimmer, brushcutter or chainsaw for a longer period - say during the winter months - should you pay a little more attention to the topic of 'care.' This will ensure that your equipment, when required, will be ready for action. To get the equipment ready for winter, clean it first. The air filter, the cylinder fins, the spark plug and the dismantled cutting tool should be checked and cleaned (also see Instruction Manual). Metal parts should be lightly coated with oil to protect them from rust and corrosion. The spark arresting screen in the muffler should be cleaned or replaced with a new one. The fuel tank should be emptied. Run the engine until the fuel system is dry (Warning! Do not operate the throttle. Run the equipment only at idle speed until the engine stops!) STIHL recommends the use of STIHL MotoMix® fuel which is pre-mixed with STIHL HP Ultra synthetic oil. STIHL MotoMix® contains no ethanol and has a storage life of up to two years. STIHL MotoMix® can be left in the machine during seasonal storage. For winter storage, a dry and, if possible, dust-free and frost-free place would be ideal. You can save space if you hang the equipment. And remember: standard pump gasoline deteriorates. To avoid problems, only purchase enough fuel that can be used within sixty days unless it is STIHL MotoMix®. Please refer to the Maintenance Schedule which can be found in the Instruction Manual.

Learn more about fuel concernsRead more about storing your outdoor power equipment

My file does not appear to fit my new STIHL chain correctly. Is the chain defective?

Note that most brands of new saw chain will not exactly match the shape and fit of a round file radius and is not a defect in the chain. When STIHL saw chain is manufactured, the cutter teeth are shaped to precise angles with highly specialized machines to provide optimum performance of the new saw chain. After the manufacturing process, a simple round file of specific diameter with the appropriate file guide is recommended to help more easily maintain the cutting performance of your saw chain. While a new saw chain does not exactly match the shape and fit of a round file, a few strokes of the correct file diameter with the appropriate file guide will quickly form the shape of the cutter tooth to match the fit and radius of the file. Click here for instructions on how to sharpen STIHL Saw Chains. Additional information and instructions can also be obtained from your STIHL servicing Dealer.

Stihl String Trimmer Serial Number Location

What size file do I use to sharpen my saw chain?

Stihl Blower Serial Number Location

- 3/8” PICCO chain is sharpened with a 5/32' round file

- .325” chain is sharpened with a 3/16' round file

- 3/8' chain is sharpened with a 13/64' round file